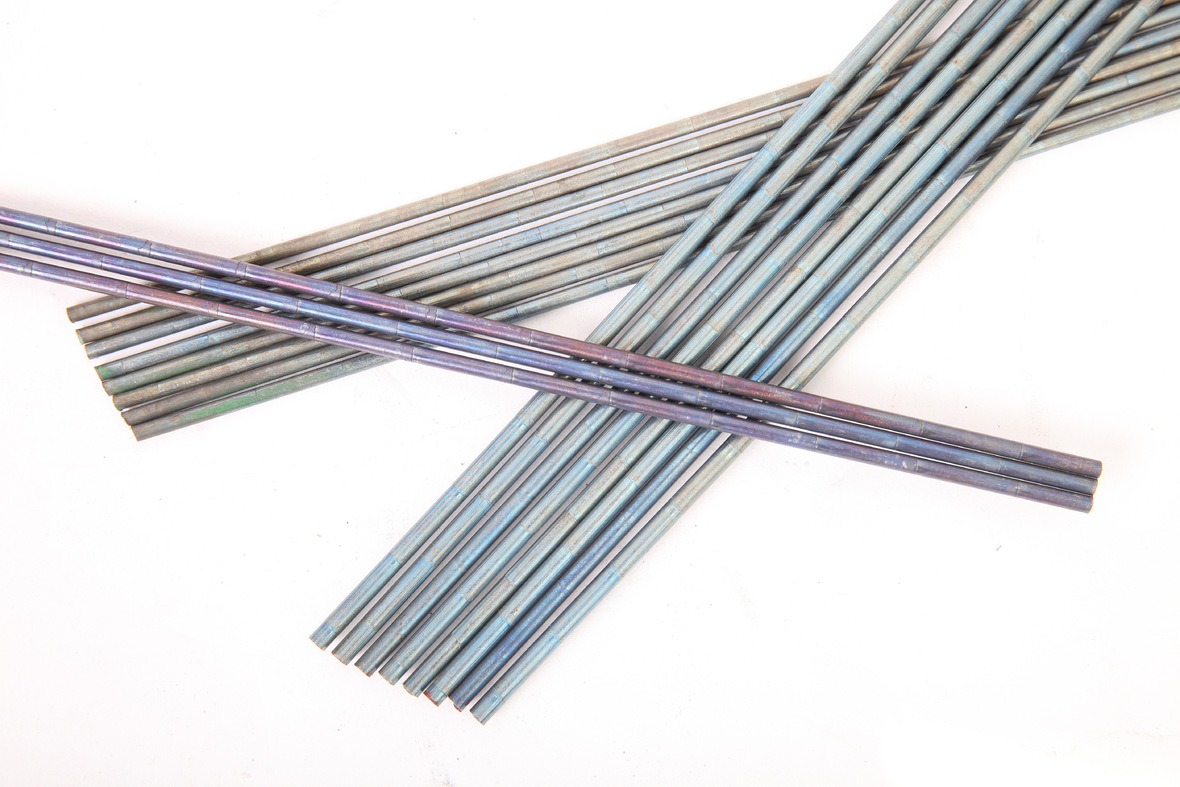

Cobalt-Based Bare Rods

| General Information | |

| Material | Cobalt-based, nickel-based and iron-based alloy bare rods |

| Specifications | ¢ 2.4-8.0 mm (¢ 1/16-5/16 in). |

| Product feature | high temperature resistance, wear resistance, oxidation resistance and thermal shock resistance |

| Application | Suitable for manual or automatic tungsten gas shielded welding (GTAW), plasma (PAW) and oxygen-acetylene gas welding (OFW).

air distribution, drill bit, petrochemical, carpentry, environmental protection, aerospace and nuclear industries |

| Grade | Main Chemical Composition(Weight %) | HRC | Application | International Reference

Standard |

|||

| Cr | W | Ni | Co | ||||

| Co101 | 29.00 | 12.50 | ≤1.00 | Bal. | 50-60 | Used to make rotating sealing ring, gouge type bearing sleeve, drill head, etc. | BalAWS A5.21

ERCoCr-C |

| Co103 | 30.00 | 13.00 | ≤1.00 | Bal. | 50-56 | Used to make wearing panel of cracker blade, work rest of center-less grinding machine,

valveseat, guiding roll of steel rolling, etc. |

BalAWS A5.21

ERCoCr-C |

| Co104 | 32.00 | 14.00 | ≤0.50 | Bal. | 45-50 | Used to make hot pressing die of copper or aluminum alloy, hot extruding die,

dry cell die, etc. |

|

| Co106 | 29.00 | 4.50 | ≤1.00 | Bal. | 40-46 | Used to make motor spiracle, high temperature and high pressure valve sealing surface,

hot shear blade, turbine blade, etc. |

BalAWS A5.21

ERCoCr-A |

| Co108 | 28.00 | – | 2.00 | Bal. | 30-35 | Used to make steam turbine blade, copper casting die, extruding die, etc. | ERCoCr-E |

| Co112 | 29.00 | 8.00 | ≤3.00 | Bal. | 44-50 | Used to make high-temperature and high pressure valve,

shear edge, sawteeth, spiral push rod, etc. |

BalAWS A5.21

ERCoCr-B |

| Co119 | 26.00 | 14.00 | ≤1.00 | Bal. | 54 | Used to make drill head in petroleum industry | BalAWS A5.21

ERCoCr-G |

| Co120 | 32.00 | 17.00 | ≤3.00 | Bal. | 55-60 | Used to make rotating sealing ring, high pressure valve seat,

wearing pancl, etc. |

|

| Co121 | 27.00 | 0.50 | 3.50 | Bal. | 20-42 | Used to make various liquid valves, valve seats, water turbine blade,

hot forging die, etc. |

BalAWS A5.21

ERCoCr-E |

| Co125 | 20.00 | 15.00 | 10.00 | Bal. | 24 | Used for high temperature and corrosion resistant valve sealing surface,

seamless pipe through the top, die casting, etc. |

|

| Co131 | 26.00 | 7.00 | 10.00 | Bal. | 30-35 | Used to make various brass casting dies, extruding dies,

steam turbine blade, etc. |

|

| Co132 | 25.00 | 12.00 | 22.00 | Bal. | 40-45 | Used to make the in/outlet valve sealing surface of internal combustion engines. | BalAWS A5.21

ERCoCr-F |

| Co137 | 33.00 | 5.00 | 24.00 | Bal. | 44-50 | Used in sawteeth pre-protection and repair, and

used to make shear blade, spiral push rod, etc. |

|

| Co140 | 8.50 | – | 1.00 | Bal. | 50-60 | Used to make valve and roller path,

plastic extruder in strongly corrosive media, etc. |

T400 |

| Co150 | 28.00 | – | – | Bal. | 20-30 | Comparatively good high-temperature corrosion

and fatigue-resistance. |

UMCo 50 |

| Co180 | 18.00 | – | 1.50 | Bal. | 52-56 | Used to make valve and roller path, plastic extruder

in strongly corrosive media, etc. |

T800 |

Nickel-Based Bare Rods

| Grade | Main Chemical Composition(Weight %) | HRC | Application | International Reference

Standard |

|||

| Cr | Mo | B | Ni | ||||

| Ni201 | ≤0.50 | – | 1.40 | Bal. | 19-24 | Glass molds, brick molds and various forming dies. | Dameron 30 |

| Ni201M | 4.00 | – | 1.50 | Bal. | 19-24 | Glass molds, brick molds and various forming dies. | |

| Ni202 | 11.00 | – | 2.25 | Bal. | 35-42 | Feeding spiral, pump shaft, stirring blade, valve sealing surface, etc. | AWS A5.21

ERNiCr-A |

| Ni202M | 11.00 | – | 2.50 | Bal. | 35-40 | Feeding spiral, pump shaft, stirring blade, valve sealing surface, etc. | |

| Ni203 | 12.00 | – | 2.50 | Bal. | 48-54 | Pump shaft, pulp cutter, valve, extruding spirals, shaft sleeve, plunger, etc. | AWS A5.21

ERNiCr-B |

| Ni203M | 13.00 | 3.00 | 3.00 | Bal. | 53-58 | Dies, cam, plunger, outlet valve, corrosion-resistant pump, etc. | AWS A5.21

ERNiCr-B |

| Ni204 | 15.00 | – | 3.50 | Bal. | 54-60 | Pump shaft, pulp cutter, extruding spirals, drawing roller,

cam, pump blade, bush, plunger, etc. |

AWS A5.21

ERNiCr-C |

| Ni204M | 16.00 | – | 3.50 | Bal. | 57-60 | Pump shaft, pulp cutter, extruding spirals, drawing roller,

cam, pump blade, bush, plunger, etc. |

Ni 60 |

| Ni205 | 16.50 | 17.00 | V: 0.30

W: 4.50 |

Bal. | – | For heat resistance, abrasion resistance, metal wear resistance

and other conditions, such as hot pressing die |

AWS A5.21

ERNiMo-5A |

| Ni206 | ≤1.00 | 28.00 | V: 0.40 | Bal. | – | Valve sealing surface in chemical industry | |

| Ni207 | 22.00 | 10.00 | – | Bal. | – | Radiation polluted circumstance, such as nuclear industry | CAST-N |

| Ni208 | 10.00 | W: 2.00 | 0.50 | Bal. | – | Substitution for cobalt 6 | |

| Ni209 | 21.00 | W: 2.00 | 1.00 | Bal. | – | Substitution for cobalt 6 | |

Iron-Based Bare Rods

| Grade | Main Chemical Composition(Weight %) | HRC | Application | International Reference

Standard |

|||

| Cr | Mo | B | Fe | ||||

| Fe301 | 26.50 | – | – | Bal. | 54 | Used for wear-resistant, oxdation-resistant or cavitation-resistant working conditions,

such as bucket teeth, pump sleeves, sawteeth, etc. |

ERFeCr-A5 |

| Fe301M | 28.00 | – | – | Bal. | 48-54 | Used for wear-resistant, oxdation-resistant or cavitation-resistant working conditions,

such as bucket teeth, pump sleeves, sawteeth, etc. |

AWS A5.21

ERFeCr-A5 |

| Fe302 | 30.00 | – | 0.80 | Bal. | 56-60 | Used for severe wear conditions, such as gouge type drill head shaft,

excavator, cracker roller, etc. |

|

| Fe302M | 28.50 | Co: 5.00 | 0.70 | Bal. | 56-64 | Used for severe wear conditions, such as gouge type drill head shaft,

excavator, cracker roller, etc. |

|

| Fe303 | 17.00 | 2.50 | – | Bal. | 48-52 | Used in agriculture, metallurgical mines, and building materials industries

for wear-resistant parts, such as plows, blades, etc. |

AWS A5.21

ERFeCr-A3 |

| Fe304 | 30.00 | ≤0.25 | Co: 12.00 | Bal. | 38-44 | Good abrasion resistance, high-temperature resistance, thermal shock resistance,

substitution for cobalt 6 |

Tris tell alloy TS-1 |

| Fe305 | 35.00 | 0.25 | Co: 10.00 | Bal. | 46-50 | Comparatively good wear-resistance and corrosion-resistance, substitution for cobalt 12 | |

| Fe306 | 35.00 | – | Co: 12.00 | Bal. | 40-46 | Higher hardness in high temperature, substitution for cobalt 1 | |

| Fe307M | 17.00 | 14.00 | Co: 6.00 | Bal. | ≥55 | Anti-abrasive wear conditions, such as roller cone drill shaft, crusher,

mixer wear parts, substitution for cobalt 19 |

|

| Fe308 | 17.00 | – | – | Bal. | 30-38 | substitution for cobalt 21 | |

Contact us

How can we help you?

More Products

-

Forged Alloy

Wear Resistant Products -

Powder Metallurgy

Wear Resistant Products -

Precision Casting

Wear Resistant Products -

Centrifugal Casting

Wear Resistant Products