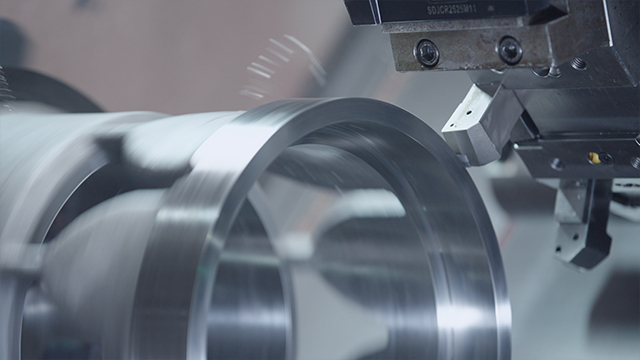

The company adopts a proprietary process and uses processing equipment to deep-process the produced casting blanks, forging blanks, and surfacing blanks to reach the finished state. The company has more than 80 sets of advanced machining centers, CNC machine tools, three-coordinate measurement, pneumatic measuring instruments and other equipment. It has rich experience in processing high-temperature corrosion-resistant alloy products, especially in the machining of special alloy materials such as cobalt-based products and nickel-based products. Rich experience in aspects. The main processing products are pump bodies, impellers, valve bodies, valve stems, bearings and other products made of high-temperature corrosion-resistant alloys.

Cobalt-based and nickel-based high-temperature wear-resistant and corrosion-resistant alloys are difficult to process. For example, cobalt-based materials are hard and brittle and are prone to chipping. Nickel-based materials stick to the knife, the cutting temperature is high, and the tool tip is easy to burn. The company’s self-developed high-temperature wear-resistant and corrosion-resistant alloy industrial parts processing technology, through special process settings, tool selection, chip removal design, coolant concentration adjustment, linear speed and feed rate control, etc., can make pressure-bearing parts and sealing The parts reach the degree of random interchange, and the technical requirement that the flatness of the cobalt-based seal is less than 1 micron is realized.

Contact us

How can we help you?

More Products

-

Forged Alloy

Wear Resistant Products -

Powder Metallurgy

Wear Resistant Products -

Precision Casting

Wear Resistant Products -

Centrifugal Casting

Wear Resistant Products