Product categories

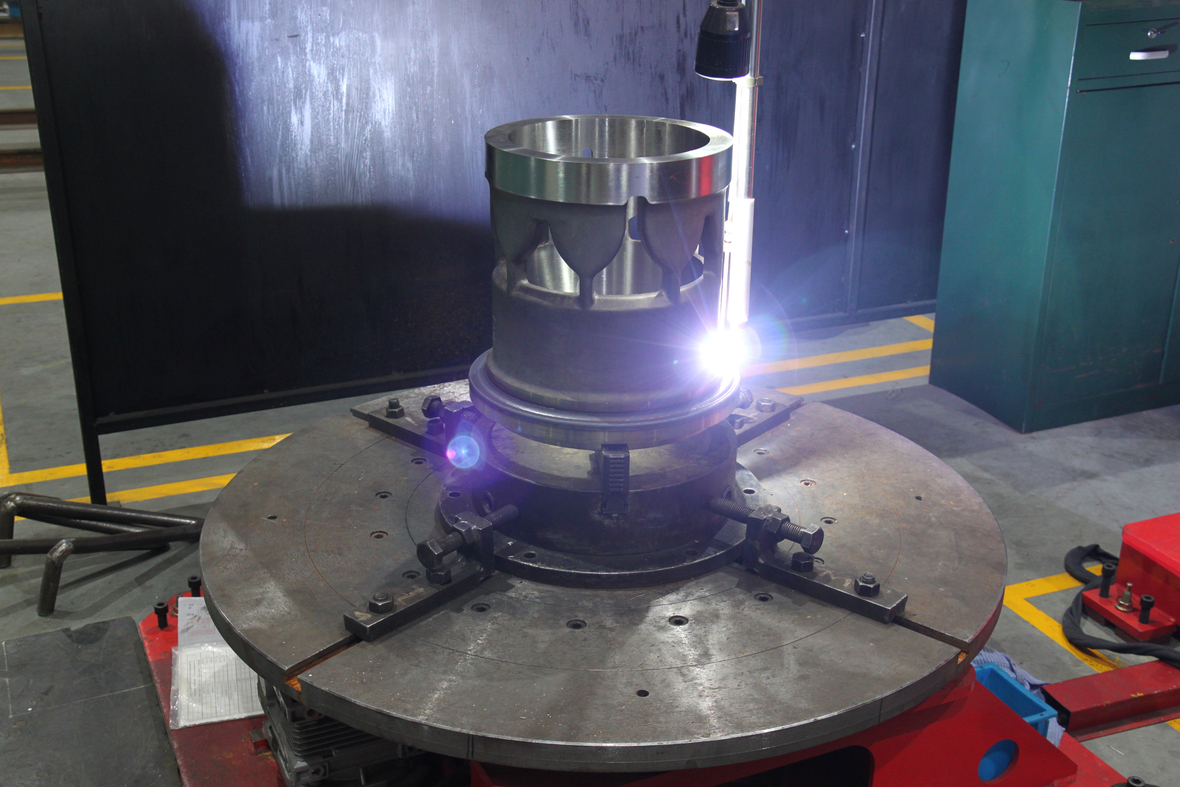

The CMT technology Advantages:

CMT technology is kind of new technology that is developed from GMAW(MIG/MAG).To overlay the corrosion resistant alloy on the low alloy steel surface to satisfy customer’s requirement to the corrosion resistant layer: Nickel based alloy, stainless steel, nickel-copper alloy, tungsten carbide welding materials.

CMT has below advantages:

Very stable electric arc, spatter free welding; small welding deformation; small heat input; low Hardfacing layer dilution rate; To control the Fe content under 5% at the 2.5mm machined hardfacing layer can ensure the corrosion resistance property of the clad layer; high welding efficiency(theoretically can reach 6kg/hour).

The cladding materials:

ERNi-1、ERNiCrMo-3 (Inconel625)、ERNiCrMo-4(H.C-276)、ERNiCrMo-10( H.C-22)、ERNiFeCr-1(Incoloy825)、ER316L、ER2209、ER2594、ERCuNiAl、ERNiCu-7、Cobalt alloy welding rods ect.

The application of the CMT Technology:

The cladded products are wildly used in the nuclear industry, ocean engineering, petrochemical industry, coal industry, oil refinery and boilers that requires strong capability of corrosion resistance, wear resistance, high temperature resistance and thermal shock resistance.

CMT application case:

We provide cladding service to our customers including: Cladding or coating for the sealing surface of the High temperature medium voltage valve and their components (Bonnet, body, seat ring, sleeve etc.) or the parts of the air valve, pump spindle, plunger, sealing ring which need pre-protective from corrosion or wearing etc.

Contact us

How can we help you?

More Products

-

Forged Alloy

Wear Resistant Products -

Powder Metallurgy

Wear Resistant Products -

Precision Casting

Wear Resistant Products -

Centrifugal Casting

Wear Resistant Products