Product categories

The technology features of PTA powder Surfacing:

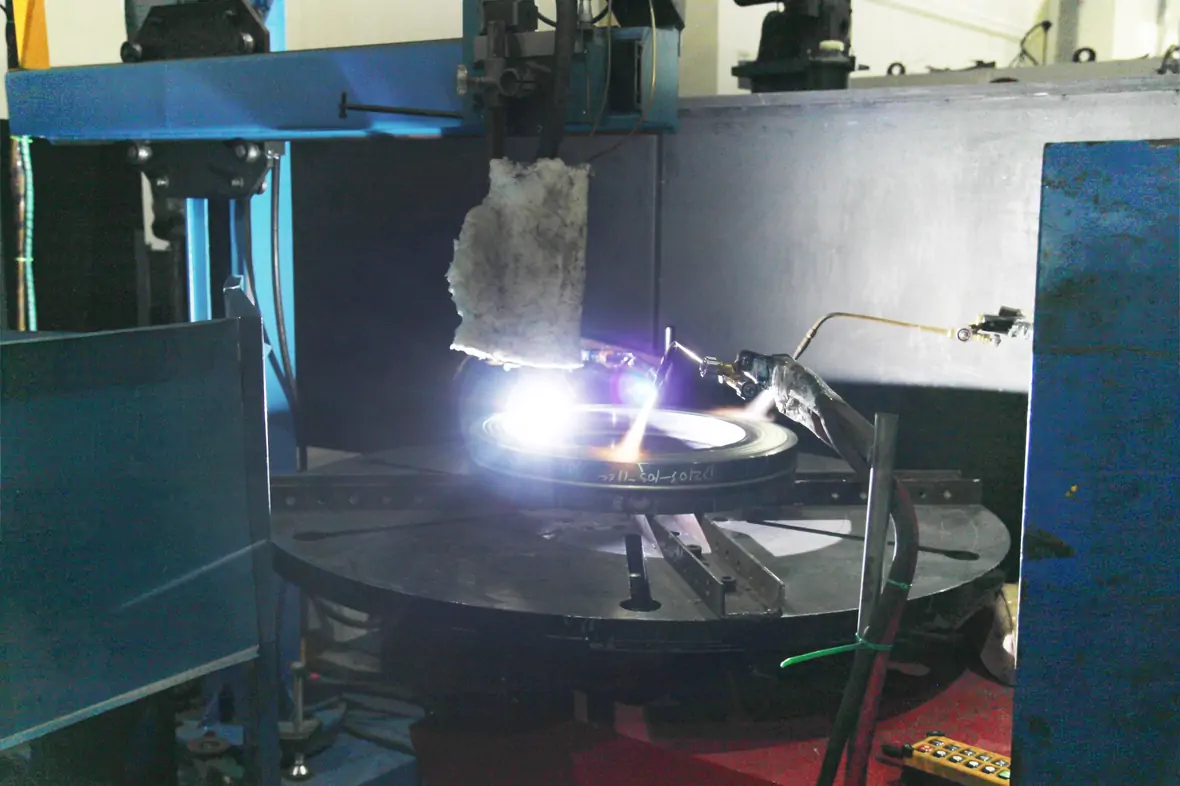

PTA welding is kind of high efficient welding method which uses the plasma that generated by the gas in the compressed arc area as its heat source and alloy powders as its filler. Compared with other normal heat sources, plasma arc has the advantages of high temperature, concentrated energy, stable arc combustion, small welding heat influence area, quick welding speed, high production efficient and easy to get thin surfacing layer with low dilution rate. It was also easier to realize mechanization and Automation for the welding process. Besides, by using PTA powder welding, fine microstructure and good welding appearance, glossy and smooth welding layer can be got. Only need little machining or even no machining need to be applied after welding. The welding alloy layer and the base work piece were found with good metallurgical blending. It is with strong blending strength and suit to weld on the work piece that with low melting point. As a result, PTA powder welding system is currently the most popular plasma welding method.

The materials applicable to PTA powder surfacing:

Cobalt based powder

Nickel based Powder

Iron based powder

PTA plasma powder surfacing case:

We provide our customer with PTA plasma welding products and solutions: Be used to the hardfacing and repairing of the the sealing surface of all kinds of High temperature medium voltage valve( Normal butterfly valve, ball valve, gate valve, Globe valve, check valve, safty valve etc.), oil drill pipe, bearing, air valve, pump spindle, Excavator shovel teeth, Nozzle vane, Chemical fiber cutting tool ect. Widely be used in petrochemical industry, construction machinery, mining machinery and powder station valves etc.

Contact us

How can we help you?

More Products

-

Forged Alloy

Wear Resistant Products -

Powder Metallurgy

Wear Resistant Products -

Precision Casting

Wear Resistant Products -

Centrifugal Casting

Wear Resistant Products