|

General Information |

|

|

Material |

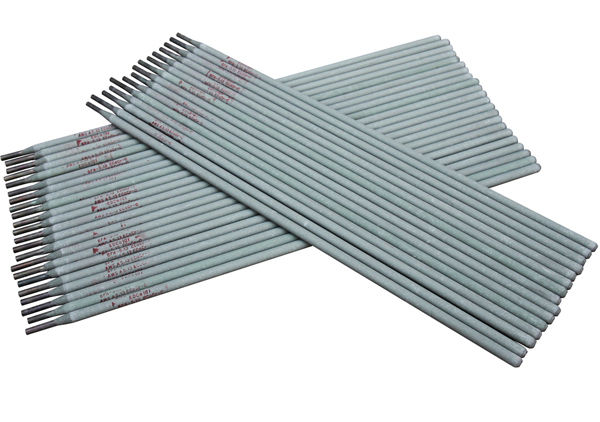

Cobalt-based, nickel-based and iron-based electrodes |

|

Size |

¢ 2. 4-5.6 mm (¢ 1/16-7/32 in) |

|

Product feature |

Good corrosion-resistance, oxidation-resistance, scratch-resistance, thermal shock resistance and intermetallic wear resistance at room temperature and high temperature |

|

Application |

High-temperature and high-pressure valves, pumps, shearing tools, guide rollers, valve sealing surfaces, roller bit bearings, centrifugal cracking pump shaft sleeves in the petroleum industry |

Cobalt-Base Electrodes

| Grade | Main Chemical Composition(Weight%) | HRC | Application | International Reference

Standard |

||||

| Cr | W | Fe | Ni | Co | ||||

| EdCo101 | 29.00 | 14.00 | 5.00 | 3.00 | Bal. | 50 | Used to make rotating sealing ring, gouge type bearing, sleeves,

valve seat, cutter edge, etc. |

AWS A5.13

ECoCr-C |

| EdCo106 | 29.00 | 4.50 | 5.00 | 3.00 | Bal. | 40 | Pressure valve, hot shear blade, turbine blade, etc. | AWS A5.13

ECoCr-A |

| EdCo112 | 29.00 | 8.50 | 5.00 | 3.00 | Bal. | 44 | Used to make high-temp and high pres valve, shear edge,

sawteeth, spiral push rod, etc. |

AWS A5.13

ECoCr-B |

| EdCo121 | 27.00 | – | 5.00 | 3.00 | Bal. | 20 | Used to make high-temp and high-pres valve, water turbine blade,

hot forging dies, etc. |

AWS A5.13

ECoCr-E |

| EdCo125 | 20.00 | 15.00 | 5.00 | 10.00 | Bal. | 22 | Corrosion-resistant valve sealing surface seamless pipe socket,

pressure casting dies, etc. |

|

Nickel-Base Electrodes

| Grade | Main Chemical Composition(Weight%) | HRC | Application | International Reference

Standard |

||||

| Cr | Mo | Fe | W | Ni | ||||

| EDCNi205 | 16.50 | 17.00 | 5.00 | 4.0 | Bal. | 25 | For high temperature wear and impact resistant operating conditions, such as hot pressing die, hot forging die, etc | AWS A5.13

ENiCrMo-5A |

Iron-Base Electrodes

| Grade | Main Chemical Composition(Weight%) | HRC | Application | International Reference

Standard |

|||

| C | Cr | Fe | Other | ||||

| EDCr-B | 0.20 | 13.00 | Bal. | 5.00 | ≥45 | Surfacing of valve sealing surfaces and components exposed to weak acid or gas attack | GB/T984-2001 |

Contact us

How can we help you?

More Products

-

Forged Alloy

Wear Resistant Products -

Powder Metallurgy

Wear Resistant Products -

Precision Casting

Wear Resistant Products -

Centrifugal Casting

Wear Resistant Products