In the production process of plastic and rubber, their components are affected by a combination of corrosion and abrasive wear, and ordinary materials will quickly fail. The perfection of plastic and rubber machinery directly affects the quality, output, and cost of plastic and rubber products. These machines must be able to adapt to changes in temperature and stress during the mixing and processing process, as well as the resulting changes in the properties of molten materials, and resist special working conditions such as chemical corrosion and mechanical wear. Stellite ™ The series of cobalt based alloys effectively reduce metal to metal wear of mechanical components, improve their performance under harsh lubrication conditions, tight operating clearances, and corrosive environments, and greatly improve the service life of components. At the same time, Bzzalloy produces various nickel based, iron based, and composite carbide wear-resistant alloys, providing customers with more diverse choices. We also provide customers with various services such as precision casting, coating processing, and equipment design and manufacturing, providing one-stop solutions for customers in the rubber and plastic industry. At present, our main products for customers in the rubber and plastic industry include wear-resistant, corrosion-resistant surfacing materials and centrifugal casting materials, customized plasma powder surfacing equipment, as well as professional casting, powder metallurgy, and coating products.

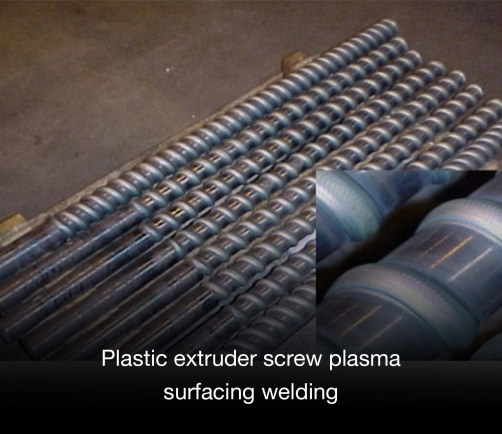

Typical Applications